Call at: +91 98250 97072

MFG. Facility

- Home

- MFG. Facility

MACHINERY AND MANUFACTURING FACILITY

Indotech bimetal is dedicatedly using inline production driven by erp system, which is linked with each and every process quality check at every stage.

our manufacturing process sequence is established with our vast experience.

The company’s focus has been on investing in the right people and right technology to deliver the best quality in the industries. and it maintain complete confidentiality about the customer’s design & drawing. indotech bimetal is manufacturer and supplier of bimetallic barrel set like: barrel, screw, ring plunger set, injection head & nozzles etc.. comprehensive quality management systems enables indotech bimetal to deliver product and services that meet and exceed the expectation of customer. as part of the company’s corporate way of life, motivated efforts are made towards continuant improvement and competency enhancement at all levels.

Machine

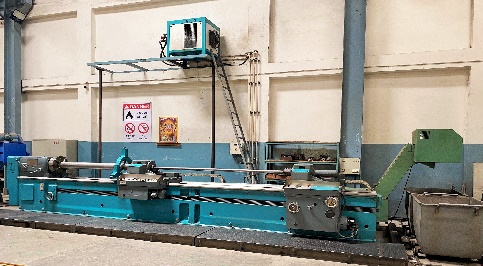

Cylinder Production Line

We have high precision cnc / scada based production line which is provide two jobs per hour production with human error free.

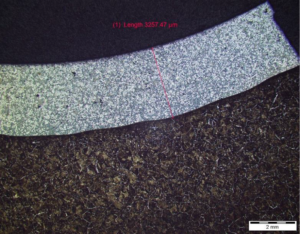

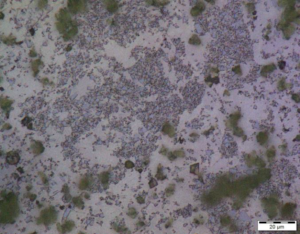

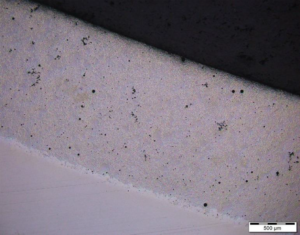

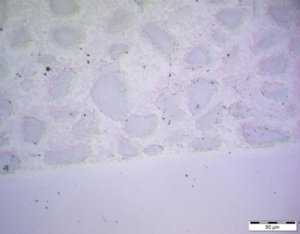

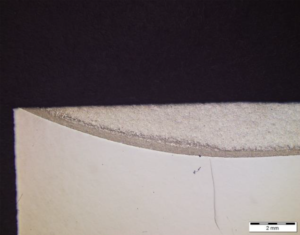

Microscope Images

We inspect micro structure with microscope for micro structure, bonding, cracks, slags etc….

We inspect wear test as per astm g65a methos for checking test piece from batch production for improve high wear resistant material analysis and control repeated quality parameter.

Deep hole Drilling Machines

(VDF V800 BOEHRINGER GOPPINGEN – GERMAN MAKE)

Machine range of drill Ø50mm to Ø225mm and a depth up to 6000mm Length

(TBT B3S B-Series Tiefbohrtechnik GmbH + Co – GERMAN MAKE)

Machine range of drill Ø50mm to Ø150mm and a depth up to 3200mm Length

(VDF V600 BOEHRINGER GOPPINGEN – GERMAN MAKE)

Machine range of drill Ø25mm to Ø120mm and a depth up to 2200mm Length

Honing Machine

(Working size Ø50 to Ø140mm and length 3400mm – Horizontal Type)

(Working size Ø70 to Ø350mm and length 5000mm – Horizontal Type)

(Working size Ø20 to Ø125mm and length 1700mm – CNC Vertical Type)

CNC Turning Center

(C600 – Taiwan Make)

Working Size Ø550 x 350L and Ø350 x 4200L

(C500 – Taiwan Make)

Working Size Ø550 x 450L

Horizontal boring machines

(TOS – GERMAN MAKE) Working size X-1400 Y-1200 Z-1500

(TOS – GERMAN MAKE) Working size X-1200 Y-1200 Z-1400

(SCHAEMANN – GERMAN MAKE) Working size X-1200 Y-1200 Z-1400

CNC VMC 4axis

(JOHNFORD 2000 HD – TAIWAN MAKE)

Working size X-2050 Y-1100 Z-800 BT-40 ATC-40

- Lifting & handlings devices

Radial Drill machines

RM65 HMT

RM63 Energy

Milling machines

(Working size X-1000 Y-300 Z-300 – GERMAN MAKE)

(Working size X-100 Y-400 Z-400 – GERMAN MAKE) (Horizontal, Vertical & Universal)

Lathe machines

Working size Ø1000 x 5000mmL

Working size Ø450 x 6500mmL

Working size Ø450 x 4000mmL and many more……

Cylindrical grinding

Working size Ø250 x 2000L

Surface Grinding machines

(Working size X-1200 Y-1200 Z-1400 – GERMAN MAKE)

FABRICATION RELATED MACHINERY

Welding Machines (ARC , MIG & TIG)

- Gas cutting machines

- Plasma cutting machines